In the Advanced Manufacturing program, students engage in the design, prototyping, and manufacturing of products and devices that drive modern life. We prepare students to enter a number of professional fields, including: engineering, CNC machining, product design, manufacturing, and more. Students can expect to learn the skills engineers, machinists, and technicians use to identify, solve, and create solutions to the world’s problems.

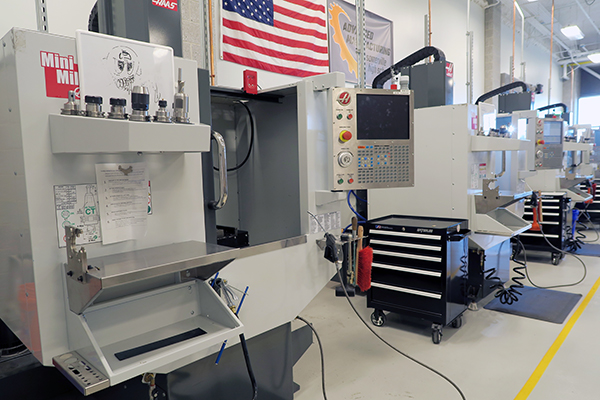

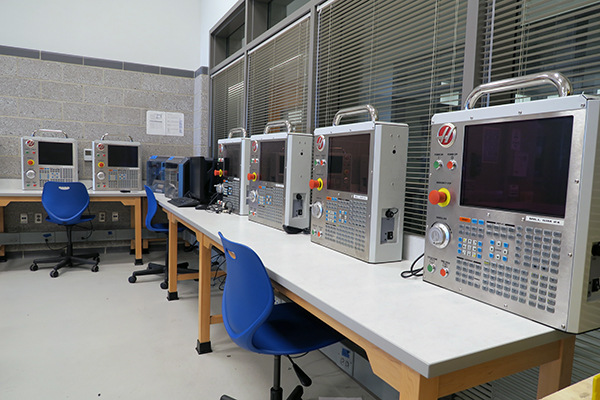

Students start by learning and practicing the math, materials, and manual machining basics needed to understand modern manufacturing. They progress to the use of digital fabrication techniques to create 3D computer models, using software such as Solidworks, and learn how to transform these models into physical objects. Students create these physical objects using state of the art manufacturing technologies such as 3D Printing, Plasma Cutting, CNC Machining, Laser Engraving, CNC Routing, Electronics and Computer Programming. Students will use these technologies in Somerville High School’s new FabLab and Advanced Manufacturing Shop.

All aspects of the shop prepare the graduate with skills and knowledge to enter the manufacturing work force or pursue post-secondary education in engineering.

Staff

Licenses

- OSHA-10

- MACWIC Certification

Program graduates work at the following companies

- Dale Engineering

- Logan Surgical Instruments

- Nevron Plastics

- Palmer Manufacturing

- Eastern Tooling

- Prattville Machine Co.

- Conant Controls

Our State-of-the-Art Advanced Manufacturing Studio